Washing Machine Standpipe Science: Height, Venting, and Why It Overflows at Night

If your washer standpipe only seems to overflow when you’re finally off the clock—late evening, overnight cycles, or that Sunday “catch-up” load—you’re not imagining it. Laundry drains are the most misunderstood branch in the house, and tiny mistakes in height, venting, and maintenance add up to big, bubbly messes. This guide explains how a standpipe is supposed to work, why it fails (especially at night), and the fixes that actually last—from lint control and detergent choices to jetting + camera diagnostics and small code corrections.

If you’re mopping between cycles or the standpipe already burps water on the spin drain, skip to the end and book Drain Cleaning. Want a tidy punch-list visit (new hoses, hammer arrestors, vent/height check, leak sensors)? Tap All Services and we’ll handle it in one trip.

Free resource to include when you publish: ICC plumbing code commentary (public excerpts). It’s a helpful primer on trap sizes, standpipe geometry, and venting concepts (always verify local amendments).

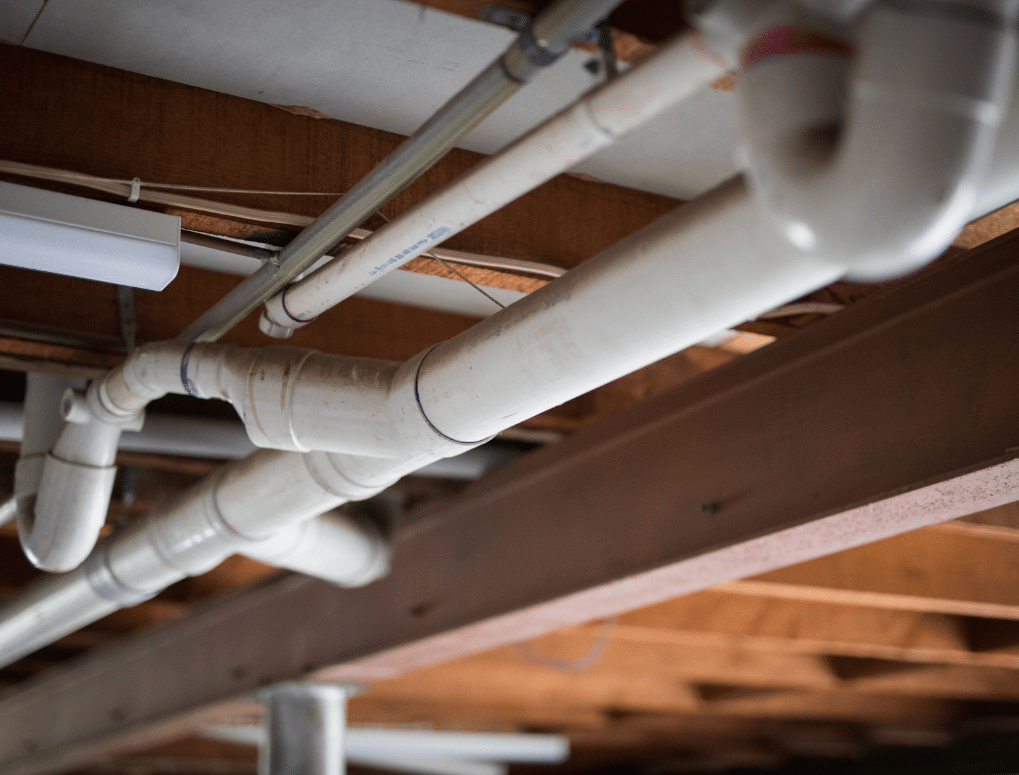

Standpipe 101: What this skinny pipe is actually doing

A laundry standpipe is a vertical receptor that accepts high-volume discharge from a washer’s pump. The basics:

Trap & seal. There’s a P-trap below the standpipe that keeps sewer gas out. That water seal must remain intact—too much suction or a missing vent and the trap pulls dry.

Height & air space. The standpipe must be tall enough to prevent splash-over and short enough that the washer pump can lift into it without stress. It also needs enough air gap around the hose so the standpipe can breathe as water rushes by.

Diameter & slope. Laundry moves a lot of water fast. Undersized pipe, long flat runs, bellies, or scale will turn a healthy drain into a foamy geyser.

Local code decides the exact numbers, but the science is constant: give the branch enough pipe, enough vent, and a clean interior, and it will swallow even aggressive spin-cycle surges.

Why the standpipe “chooses” to overflow at night

Three practical reasons we see this all the time:

Detergent gel + cooler pipe temps

At night, garage/crawl temps drop. Cold pipe walls + high-efficiency detergent create suds and gel that cling to rough spots, partially narrowing the line. The first loads seem fine; the second or third pushes the restriction over the edge.Stacked demand

Evening is when many homes run the dishwasher, irrigation top-offs, and showers around the same time your washer discharges. Any shared vent or partially obstructed main will show up as a laundry overflow first—the pump outpaces the branch’s ability to breathe.Softener regeneration

Water softeners often regenerate at 2–3 a.m. and dump brine to the same standpipe or branch. If the line is even slightly restricted, the overnight regen cycle is the straw that breaks the trap’s back.

The short list of real failure modes (and how to spot each)

Standpipe height error. Too low = splash/overflow; too high = washer works harder and may siphon back. A quick tape measure and a look at the manufacturer’s specs tell the tale.

Vent or AAV problems. Gurgling after the drain, or a trap that smells sewer-y, points to poor venting. A vacuum forms, the trap seal gets disturbed, and flow slows with each load.

Trap or branch restriction. Lint, detergent paste, and biofilm create a soft choke that a cable might poke through but won’t remove. Smell returns quickly; overflow returns under peak flow.

Belly/sag in the run. Camera shows standing water between cycles; suds hang out and harden.

Undersized pipe or long flat run. Common in older retrofits; the line simply cannot carry modern pump volume.

Washer hose jammed airtight. The hose stuffed deep into the standpipe seals the top and kills the vent air space. You’ll hear chugging and see splash even in a clean line.

A fast homeowner diagnosis (10–15 minutes, no tools needed)

Watch & listen during a rinse/spin.

Loud glug-glug and slow return to quiet = venting issue.

Sudsy foam collar around the standpipe top = detergent gel + restriction.

Splash at the top only when the hose is deep = hose too far in.

Pull the hose up an inch. Restore air space around it. Overflow improves? You found one culprit.

Detergent sanity check.

Use HE detergent and measure it. Excess soap doesn’t clean better; it makes stable foam that rides the line.Five-gallon bucket test.

Pour steadily into the standpipe. If it backs up without the washer running, the branch is restricted or vent-starved.

If any of these point to restriction or venting, the right next step is a camera + jet, not another cable poke.

Lint, detergent, and biofilm: why cables don’t solve laundry lines

Laundry branches fail differently than a kitchen or bath:

Lint mats. More like felt than a hairball—cables drill holes through but leave the mat.

Detergent paste. Think wallpaper paste mixed with dryer lint; it recoats quickly.

Softeners & additives. Some products make suds more stable; more stability = more carry and longer foam columns in vertical pipe.

That’s why our go-to is a degreasing jet nozzle sized for your pipe. It scrubs the wall clean, pulls the lint out, and restores capacity end-to-end.

Venting basics: the invisible half of the drain

A high-volume receptor like a laundry standpipe needs air moving freely to prevent the trap from being siphoned and to keep the water column smooth. Clues that venting is the issue:

The standpipe gurgles for 10–20 seconds after flow stops.

You smell sewer gas near the box—trap seal is disturbed.

Multiple fixtures talk to each other (tub burps when the washer drains).

Fixes range from raising an AAV to the correct height, replumbing a trap arm with proper slope, or—when walls are open—adding the right vent tie-in. During Drain Cleaning we camera the branch and, if needed, smoke-test or pressure-test the vent path; any code corrections can roll into All Services with photos and a simple scope.

Height & geometry: what “right” usually looks like

Exact dimensions come from your local code and the washer manufacturer, but in plain English:

The standpipe rises high enough to prevent splash and give the hose an air gap.

The P-trap sits close to the receptor with a properly sloped trap arm to the branch.

The pipe diameter and trap size match laundry’s real flow rate.

The vent connection is placed so the trap keeps its water seal under full pump discharge.

If your standpipe is barely taller than the hose, or the trap is buried way down the wall, you’re fighting physics. A quick box re-build with correct geometry often cures “mystery” overflows for good.

Why branch jetting + camera beats guesswork

Here’s our typical laundry service sequence:

Camera from the standpipe to the tie-in, then on to the main. We note belly depth, transitions, lint mats, and any scale.

Hydro-jet with a degreasing/lint nozzle (not a generic tip). We clean backwards on the way out to pull debris to the standpipe.

Final camera pass to verify bare wall and confirm vent tie-in and slope look healthy.

If the camera shows a long belly or an undersized, flat run, we’ll price a short code correction that pays for itself in avoided callbacks.

Because laundry lines re-foul fast, we usually pair jetting with two cheap habit changes (below) so your branch stays clear.

Two habit changes that extend the life of a clean branch

Measure HE detergent (don’t eyeball). Use less than you think; modern washers need very little.

Add a lint strategy. A mesh lint sock on the washer hose is a quick start; better is an inline lint filter you can service every few weeks. If you’re on septic, this is extra important.

Nighttime insurance: overflow containment and early warning

Even a perfect drain benefits from a little insurance:

Washer pan + drain (or a water sensor) under upstairs laundry.

Angle stops that actually turn and braided stainless hoses with date labels.

Hammer arrestors if you hear pipe slap at fill or spin cycles.

We can bundle these into a single All Services visit. Cheap parts, big protection.

Troubleshooting cheat-sheet (what it looks/sounds like)

| Symptom | Most likely cause | What fixes it |

|---|---|---|

| Gurgling 10–20 sec after drain | Vent path issue / AAV too low | Raise/replace AAV, correct trap arm/vent tie-in |

| Overflow only on 2nd/3rd load | Lint/detergent gel, partial restriction | Jet with lint/degreasing nozzle + camera verify; add lint filter + measure HE soap |

| Overflow on regen night | Softener discharging to same branch | Jet branch; reroute softener to approved receptor if needed |

| Splash at standpipe top, hose jammed | Airtight seal choking air gap | Pull hose up, secure with clip, leave air space |

| Musty smell at box | Trap siphon or dried trap | Fix venting; ensure trap stays wet; add prime if needed |

| Suds belching from standpipe | Soap overuse + restriction | Reduce soap, run “hot clear” cycle, jet branch |

“Do we need to upsize the pipe?”

Sometimes. In older retrofits the laundry was tied into a bath group on small pipe with little fall. Upsizing the trap/standpipe and giving the branch a proper slope changes everything. We confirm with camera measurements and recommend the smallest change that solves flow—often a short section, not a whole-house repipe.

A realistic, step-by-step plan

Stop the mess. If it’s actively overflowing, don’t run more water. Call for Drain Cleaning and mention “laundry overflow”—we’ll bring the jetter and the right nozzles.

Prove the cause. Camera the standpipe-to-main run and mark any bellies or dodgy transitions.

Clean to bare wall. Jet with a lint/degreasing tip; verify with a final camera pass.

Correct small code misses. Adjust standpipe height, trap arm slope, or AAV/vent tie-in as needed.

Add prevention. Inline lint filter, measured HE detergent, and (if you have one) softener discharge routed to an approved receptor.

Optional quick wins. Braided hoses, hammer arrestors, labeled shutoffs, and a water sensor in the pan.

That sequence ends the cycle of “fine for a week, then a flood.”

Case study (Boise garage laundry)

Home had a late-night overflow every few weeks. Camera found: long belly in a 15-foot garage run, heavy lint paste at the low spot, and the washer hose jammed halfway down the standpipe. We jetted, raised the standpipe, pulled the hose back to restore the air gap, and added a small overhead re-route for the belly section during a same-day All Services slot. Added an inline lint filter and measured HE detergent. Result: six-month follow-up camera showed clean pipe; zero overflows through the holidays.

FAQs

Will a cable clear help in a pinch?

Maybe for a day. It drills a hole but leaves the lint mat and detergent paste behind. Jetting + camera is the cure.

Can I just pour enzyme down the standpipe?

Enzymes help prevent film, but they won’t remove a mature lint/paste choke. Use them after a proper clean.

Do air admittance valves (AAVs) work for laundry?

Where allowed, yes—at the right height and with correct trap arm geometry. Too low, and they starve the drain of air under high flow.

Is my washer the problem?

Rarely. Modern pumps move water fast, but a correctly sized, vented, and clean branch swallows that flow. The plumbing, not the machine, is usually the bottleneck.

Bottom line

Nighttime laundry overflows aren’t bad luck; they’re the predictable result of restriction + poor venting + small geometry misses. Clean the branch to bare wall with the right nozzle, prove the layout with a camera, tweak height/vent to code, and add two simple habits—measured HE detergent and lint filtration. Do that once and your standpipe will behave, even on back-to-back loads.

Ready to stop babysitting the spin cycle? Book Drain Cleaning and we’ll clear, jet, and camera-verify the fix. Want the whole laundry corner tuned—hoses, arrestors, vent height, leak sensor, and documentation? Schedule All Services and we’ll make it easy.